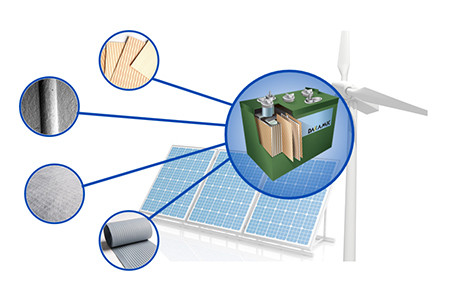

Key lead acid battery types for stationary & specialty applications, like renewables are flooded & gelled electrolyte. DARAK, a microporous duroplastic separator from Daramic is best suited to provide high temperature stability in gelled applications, while Daramic industrial grade separators meet flooded flat-plate or tubular design needs.

Profile

The profile design plays an important part in the spacing of components in lead-acid batteries. As its name suggests, the separator acts as a barrier between the positive and negative electrode. The spacing in between the two components is guided by the profile design. Daramic offers many profile combinations that can meet most any battery design requirement need.

Formula

In support of the chemical reaction that takes place inside of a lead-acid battery, the material formulation of the separator provides key benefits and can be adjusted depending upon the battery application. Properties adjusted through the formula include permeability, porosity, pore size distribution, electrical resistance, antimony suppression, ionic conductivity, and chemical compatibility within the electrolyte.

Lamination (Optional)

A key failure mode of some battery types is active material shedding. Laminates, which can be attached through adhesion are typically a glass material fiber available in various thicknesses which act as a support in maintaining active material on the electrode. Additional benefits of lamination include acid mixing and mechanical stability.

Form

Daramic’s production flexibility allows delivery of a finished product that aligns with customer manufacturing needs. Separators can be provided in the following forms (with or without laminated material):

- Jumbo Roll

- Slit Roll – state- of-the art slitters deliver uniform width control

- Cut Piece –cut to requested width and length using quality controlled choppers for repeatable, consistent results

- Envelop or sleeve – mechanically sealed, which allows easier insertion of the electrode

Stationary / Specialty

Daramic® IND CL™

Daramic Industrial is a high-performance polyethylene battery separator designed for high quality industrial battery applications. Unique rib designs are available for flat-plate and tubular battery designs.

Darak®

DARAK is a microporous duroplastic separator. Due to its high temperature stability, low electrical resistance and very low acid displacement, DARAK 2000 & 2003 separators are suited for batteries with gelled electrolyte or in conventional flooded high performance batteries.

XCharge™

XCharge meets industrial, flat plate battery needs for abusive cycle applications such as inverter, renewables, mining & railroad, & motive power. The separator enhances flooded cycling performance & battery life targets through a special water loss formula & cross negative rib design.

HiCharge®

HiCharge helps to extend battery life in motive power applications through a special waterloss feature and unique profile design. As motive power batteries experience increased operations in partial-state-of-charge, Daramic HiCharge helps defend against accelerated grid corrosion and acid stratification, thus increasing battery life.

Daramic® HD Plus™

Daramic® HD Plus™ builds upon the success of the Daramic HD product line with an improved formulation designed to further reduce water loss, reduce maintenance, and increase abuse tolerance in heavy duty deep cycle applications such as golf car, renewables , floor machine, and traction vehicles.