People

Daramic R&D Centers feature chemists, material scientists, & process engineers working towards the goal of improving existing products and delivering new solutions that meet customer needs.

Daramic R&D Centers

Our team of skilled industry experts, combined with state-of-the-art product development, material analysis, pilot manufacturing & testing facilities, can serve as an extended resource for our customer technical team.

Owensboro, Kentucky USA

Gujarat, India

Selestat, France

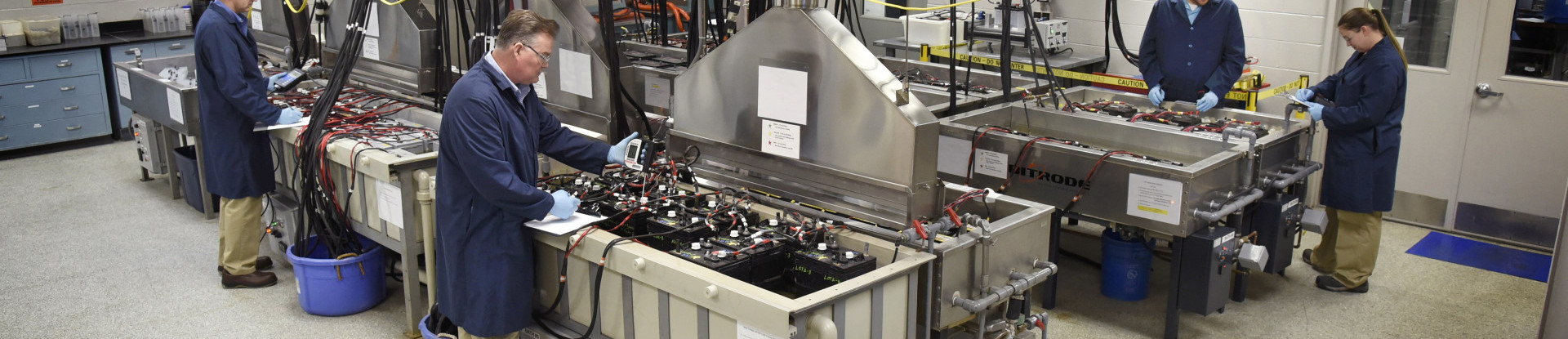

Advanced Battery Testing

On all types of parkways, paths, and aisles, vehicles and the lead acid batteries they carry are moving. A key to understanding how the battery functions – including its failure modes – is to mimic real world scenarios during testing.

Daramic, in partnership with Huff Technologies®, has developed a proprietary testing method along with innovative new machinery. The Daramic® Shuttle Table™ creates a battery testing paradigm shift that simulates how batteries operate in the real world.

Daramic® Shuttle Table™ by Huff Technologies®

Battery Testing

Every Daramic R&D Center contains a fully functional battery testing laboratory, which allows better partnership with our customers in product development and product improvement.

Charge – Discharge Cycling Units

High-Rate Discharge Units

Temperature Controlled Baths

Capabilities to Hand Manufacture Batteries

Battery Teardowns for Failure Analysis

Proprietary Motion & Rocker Table Testing

Computer Modeling Capabilities

By simulating the start-stop motion resulting from vehicle acceleration and braking, computational fluid dynamic (CFD) modeling capabilities has enabled Daramic to design separators that promote electrolyte mixing within the battery

Electrolyte Mixing Model - Optimized Mixing Rib Design

Electrolyte Mixing Model - Solid Rib Design

Analytical Capabilities

Daramic has complete analytical equipment to test material for a wide variety of physical, chemical and electrochemical properties of microporous materials including:

- Inductively-coupled plasma spectroscopy

- Fourier-transform infrared spectroscopy

- Cyclic voltammetry

- Mercury porosimetry

- Scanning Electron Microscope (SEM)

- Electrochemical lab